The webbing utility strap - reinvented

Elliot Brown founders Ian and Alex enjoy a long history in the watch industry but an even longer one making watch straps. You may recall the Animal watch strap that used a piece of webbing against the skin, with a Velcro outer that easily passed through the watch pins and wrapped around the wrist in an unbreakable loop. They invented it, sold around a million per year and they became a kind of badge of honour, with bright colours worn discreetly under work suits, at school, across the boardsports community, the military and beyond. The straps helped to take the business to many highs, sponsoring the first ever UK National Points Series Mountain Bike Championships, the European Freestyle Snowboard Tour and the finals of the World Professional Surfing championship calendar, the Triple Crown of Surfing in Hawaii.

The straps were revolutionary but the founders have always had a version 2.0 in their sights, with all the unique elements of the original but tougher, classier, and with even better functionality.

Today Elliot Brown produce some of the world’s most durable time pieces, building to standards far in excess of any industry norm. The idea of a new webbing strap that would sit perfectly within this ethos has been ever present. Thoughts centred around a beautifully crafted webbing strap with a low profile, ultra-light, unbreakable fastening system that would allow us to totally re-imagine the single pass style webbing strap, a design that has remained largely unchanged for decades.

'G10' webbing straps are regarded as a fit for purpose item but there are some functional down sides” commented Ian, “with an average wrist, there’s a cumbersome excess of material to tuck away under retaining loops that can become bulky, snag on clothing and retain a lot of moisture. Pin holes tend to fray and users tend to have a fairly lax attitude to cleaning their webbing straps. Something our servicing team never looks forward to handling!"

"We knew that if we got everything just right, this new strap could be a game changer.”

The first buckle prototype wasn’t perfect but it demonstrated the principle we were working towards. Low profile, strong, light-weight and a cinch to use.

"When the first buckle sample landed, we knew we were really onto something and sent the design straight off to a patent attorney to explore if it was indeed original and if we could protect it."

The strap consists of two components, a technical strip of webbing and an ingenious hinged stainless steel clamp buckle. The buckle works by passing the loose end between a roller and clamp that adjusts infinitely for size then click-locks down in position and hinges, allowing the short tip to be neatly retained under the buckle's built-in retaining bar. No folding back webbing under d-rings, little moisture retention, no snagging on cuffs, no holes to fray.

Because there's no pin buckle or holes in the webbing it lasts longer and there's infinite adjustment for a perfect fit so they're supremely comfortable. Adjusting to fit over a wetsuit or jacket is s cinch too.

"We literally didn’t stop the tweaking and fine tuning until the buckle performed perfectly. We went through 3 further prototypes to reach the final version" explained Alex.

To release the buckle, it’s simply a case of pulling the webbing upwards away from the wrist which naturally flips open the clamp. It’s silent and instant and if you wanted to change strap colour on your watch, that’s a job of only a few seconds too.

“We’ve given them some stick for over a year, they're super light and the ultra-low profile. They’ve easily slotted into our daily lives and we love how strong and comfortable they are, even when wet.”

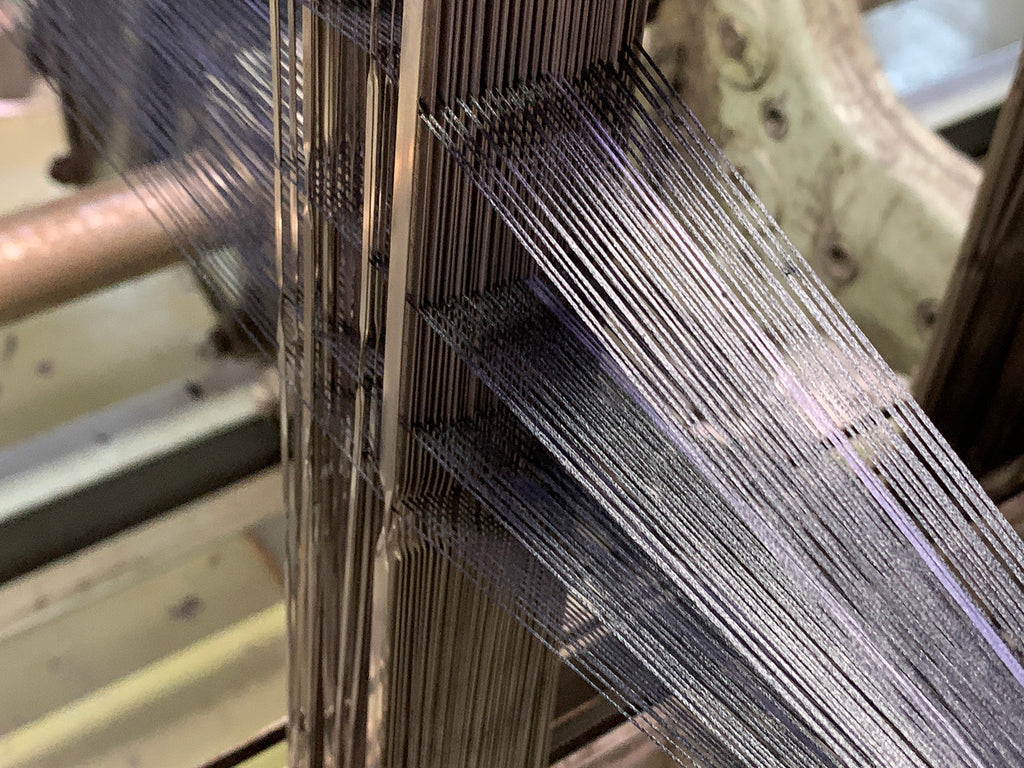

A beautifully technical slice of webbing

The webbing has its own story. We put this little clip together to show the loom in action.

We know from past experience that the most durable webbing has a woven edge on both sides – known as double selvedge. Modern needle looms can’t do this but the old Victorian shuttle looms can. 'Normal' webbing has one woven edge and one looped edge where the weft thread wraps around the longitudinal warp threads on one side but is simply looped back in on the other side - meaning it could potentially catch and unravel.

The most comfortable webbing is one with a soft handle, not too thick, not too thin, matt rather than gloss, breathable and doesn’t retain too much water. We explored every type of yarn, every weave pattern, every loom state finish and every laundered finish. Our webbing of choice is made from textured polyester yarn that has a gorgeous natural handle with a matt finish but is also tough enough to withstand being clamped in our buckle system on a daily basis. It dries quickly, it’s hypoallergenic and treated with lifetime anti-bacterial.

The webbing is woven for us by Bowmer Bond narrow fabrics, a family business founded in 1795, housed in what was once a water powered mill in Ashbourne, Derbyshire UK. The water from the lake abutting the mill still flows underneath where it used to power the water wheel.

They had painstakingly re-commissioned a Victorian shuttle loom called Dolly, perfectly suited to weaving the highest quality webbing this project demanded. Dolly runs more than ten times slower than a modern needle loom and requires constant maintenance by skilled people to constantly watch over and re-load the small bobbins of weft thread held within each wooden shuttle.

To feed the looms, textured yarn is dyed to our colour pallette in small batches and at the same time, treated to a lifetime anti-bacterial wash to avoid the odours often associated with fabric straps. Once dried it’s twisted and spooled onto cones which are wound around warp drums with approximately 90 threads on each drum. Two warp drums feed the loom as webbing emerges at a glacial pace. The result feels like pure gold.

The webbing and buckle work harmoniously. "We switched from a 4 twist yarn to a 6 twist yarn on the weft thread as that increased the density just enough to give us a more satisfying click and an even firmer hold in the buckle" explained Ian.

Each strap is minimally packaged in a natural cardboad board sleeve and available in nine colours with natural steel, bronze and gunmetal buckle finishes..

Webbing stats:

- 22mm wide with double selvedge woven edges for unrivalled durability

- Fits wrists up to 225mm (large size 255mm)

- Soft handle

- Breathable matt finish

- Low water and moisture retention

- Anti bac treated and hypoallergenic

- Friction fit between watch and strap bar on EB watches

- Textured yarn dyed in small batches